The company

Madalosso emerged with the need for large, medium and small automakers and manufacturers to meet their operational demands without having to bear the high costs that accompany the growth of a factory and, above all, always maintaining the quality required by the customer. Operating in the most diverse segments, and always acting where our customers need it most, Madalosso always delivers the needs of its customers.

Today, we have more than 3,000 m², which allow us a perfect arrangement of layout and a future expansion in our industrial park, the company also has its own cafeteria in its workplace, as well as a rest area for its employees. The company’s directors, the technical group and most of its employees have been working in the metallurgical sector for over 25 years.

Mission

Promote solutions in machining parts, being highly competitive and structured in the market.

vision

To be among the best options in solutions and in the provision of services and manufacture of machined parts in Brazil.

Values

Customer focus

Respect for others

Competence

Continuous improvement

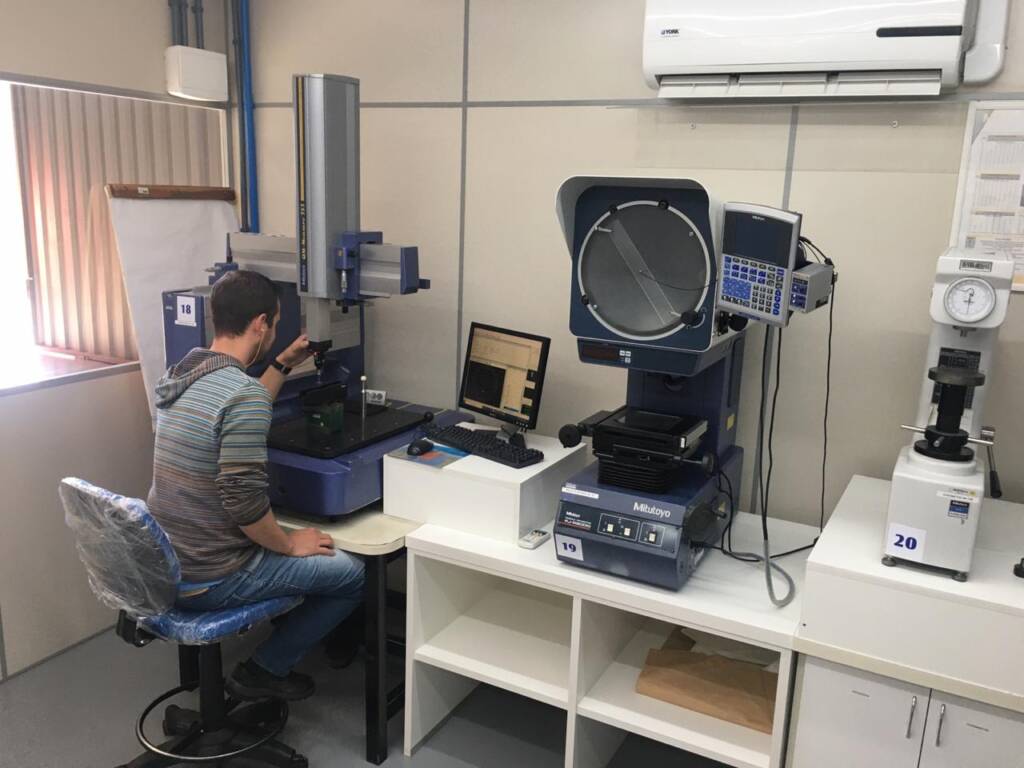

Metrology

Madalosso has its own dimensional laboratory, ensuring the necessary checks in all processes carried out in the operation. In addition to preparing control charts, PPAP studies, records of non-compliance with the preparation of action plans, using the ISHIKAWA tool, 5 whys, etc. It also operates in the monitoring of indicators, instrumentation measurement plans, in addition to maintaining contact and visits with customers.

Three-dimensional

Mitutoyo QM353

Capacity:

X 300 | Y 500 | Z 300mm

Durometer

Mitutoyo DT:10

Equipment used for

check the

hardness of the material..

Profile projector

Mitutoyo PJ-A3000

Capacity:

XY 100 x 100mm

Rugosimeter

Mitutoyo SJ400

Equipment used for

surface roughness

check

and channel: Ra, Ry, Rz, Rq and Rt